ICL 1900 Series Machines in The Netherlands

The Netherlands in the 1960's was adopting ever more "social" programs covering state pensions, widows & orphans payments, work disability payments and a plethora of similar government-funded support programs. All of these programs were administered in Amsterdam by an organization set up for the purpose, namely the "Gemeenschappelijk Administratie Kantoor" also known as GAK for short. This was located in a large building with a lot of glass - accordingly known by the locals as "Het Aquarium" and located in a part of Amsterdam called Sloterdijk, very close to a church with a steeple in the shape of a coal-hod and referred to as De Kolenkit. The ICL 1904 at GAK (Gemeenschappelijk Administratie Kantoor)

As these government programs expanded, GAK got into difficulties with its computing capability. They had a Univac Solid-State 80 (SS80) that had card input and output coupled to a modicum of compute power. But all data had to go in on punched cards, and all output was via punched cards - to be listed off-line later by conventional tabulators. Thus the SS80 could do little more than compute payments - it could not for example accumulate or integrate all information/records for a particular person. This was still had to be done by sorting and collating literally hundreds of thousands of punched cards in massive files.

It was decided that a very large computer was needed in a hurry before GAK drowned under its administrative load and as ever new programs were passed into law mandating further processing and administration. Specifically the computer would have to support heavy usage of magnetic tape so that integrated customer records could be maintained without resorting to some tons of punched cards per month.

But the operational details for these programs posed a difficulty peculiar to the Dutch environment.

Firstly, many bank transactions started out life as 80-column cards (so-called Giro kaarten) and then when used, the cards were torn down a perforated edge to make them effectively 51 column cards (much as a check is separated from its stub when it is used). Thus any new computer would need to be able to read huge quantities of 51-column cards.

Secondly, payments were processed locally throughout the country using Olivetti teller machines in every local post-office. These produced paper tape output of the standard physical width but a unique system of punching. Specifically there were no sprocket holes running down the center of the paper tape (all movement was handled by pinch rolers) and the data was encoded in square holes rather than round holes, giving rise to the designation "Square Holes In Tape" or SHIT. Thus any new computer would need to be able to read huge quantities (about 2 kilometers/day) of this paper tape.

The only card-reader on the market that could read 51-column cards was made by Control Data - but they didn't have a commercially-oriented mainframe sufficient to tackle the job.

The only paper tape reader capable of reading Olivetti tape was made by Olivetti. It was attached to a desktop teller machine and designed to read tape at a speed that matched its teletype-style printing capability - a sustained rate between 4 and 6 characters/sec under ideal conditions (no carriage returns)

The only company prepared to bid a mainframe meeting these conditions was ICL. They had access to a CDC 405 card-reader via a tight relationship with CDC and felt confident they could build a controller for it to allow connecting it to the standard peripheral interface supported by all 1900 series computers. Furthermore, because of their relationship with Elliott Computers who were industry leaders in the area of high-speed paper-tape, they were prepared to adapt an Elliott reader to handle the Olivetti paper-tape.

Thus a uniquely configured ICL 1904 was offered with the requisite card reader and paper-tape reader, together with two high-speed printers and 14 tape units and capable of running 4 separate programs simultaneously in multi-programming mode. This machine was delivered to GAK in about 1965.

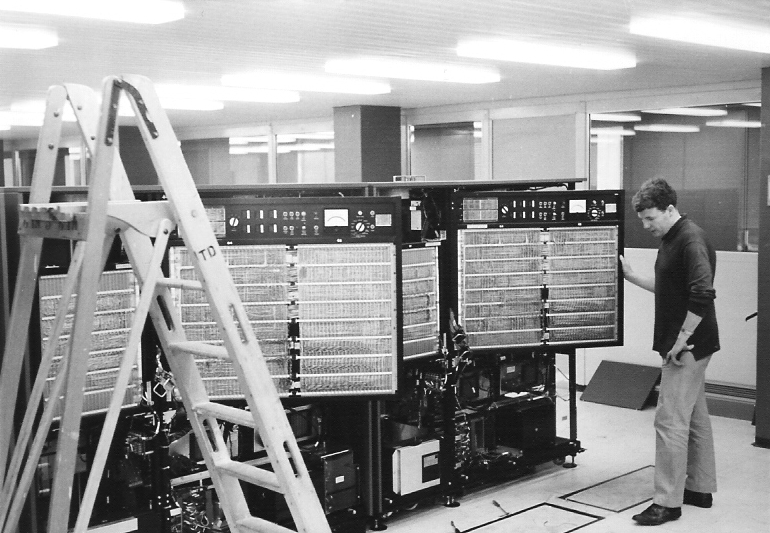

Here the mainframe itself is being installed soon after its arrival from the factory in Manchester.

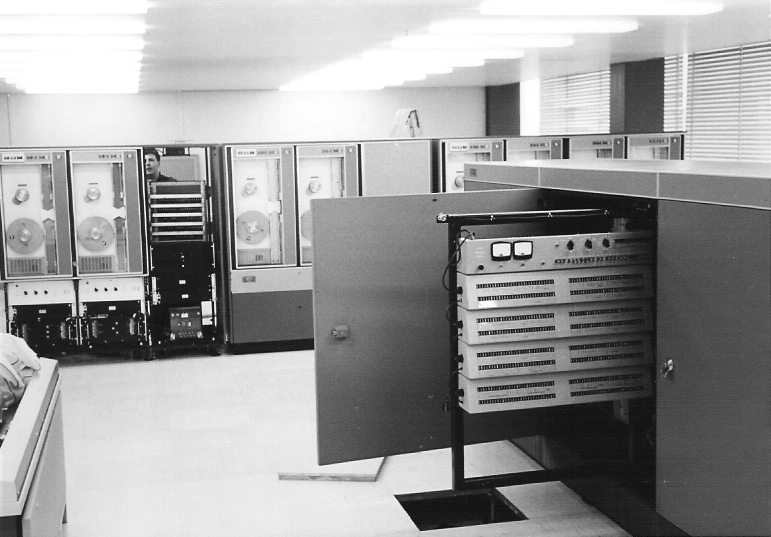

The front of the mainframe showing the engineer's panel. This displayed the contents of various registers in the machine and contained the margin controls which allowed the main clock-cycle to be speeded up or down and voltages to be adjusted in order to run margins and confidence tests. In the background are some of the banks of tape units.

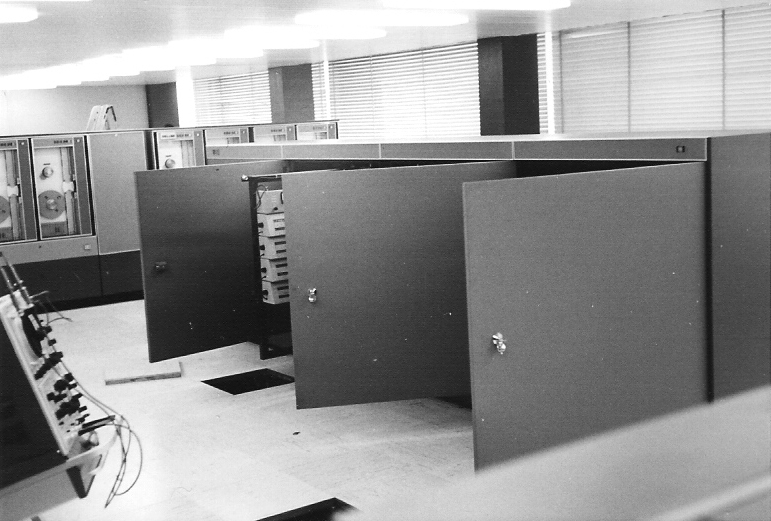

Here you can see all four bays of the mainframe itself. Each bay contained two large hinged frames (one at the front, one at the back) containing the circuitry and boards. These frames could be swung out for maintenance and test purposes to allow engineers easy access to all wiring and components. These frames were normally hidden behind the doors (which also provided isolation from electro-magnetic noise and RFI problems). The frame with the engineers control panel has been swung out and can be seen in this picture. Also notice that some of the panels in the false floor are not yet in place. All power and signal cables between the various units were routed under this false floor which also served as the plenum by which cool air entered the room from the air-condtioning units. Warm air was removed via ducts in the ceiling.

Here we have a wider view of the overall setup. We are looking over the two printers which are in the foreground. (Just in front of the printer on the right was a separate device which could be wheeled up to the back of the printer called a decollator. This device received the multi-part continuous stationary as it came out of the printer and separated/folded it into separate stacks, while at the same time removing the interleaved carbon papers by rolling them onto spindles for later disposal. Just behind the printers is the card punch, and a lttle bit further on the left (near the engineer's oscilloscope) is the operator's console consisting of a teletype mounted on a desk.

In the further distance we are looking end-on at the mainframe which has its doors open, and behind that the tape units.

Here we are looking in the opposite direction at the card punch and behind it the two printers. Behind the left-hand printer we can see the decollator.

A closer look at some of the tape units. At this point, only eight were installed. Another six were added soon after initial installation to permit fuller use of the ability to run four programs simultaneously.

When the 1904 was originally ordered, there was some doubt as to whether a single machine could tackle the whole processing load of all the government programs that were administered by GAK. Accordingly a backup plan was created to allow doubling of the processing power. The process experts maintained that merely putting in a second machine would not solve the problem, but that a single integrated computing entity would be required where information for a given "customer" (e.g. pensioner, widow, orphan, unemployed, disabled, etc. etc.) must be processed in its totality - simultaneously as a single entity and not in separate jobs/applications for each welfare program. This was estimated to require simultaneous access to 10 tape units from seven separate programs operating in multi-programming mode with the ability to exchange information between the operating programs in real time as each handled some aspects of some welfare program(s) for the customer. Postscript

The backup plan envisaged two 1904 mainframes (each capable of running four user programs simultaneously) but interconnected through a special device which would have to be built for the purpose. This device was to be based on a drum (think of it as a disk but cylindrical in shape with a series of read/write heads permanently mounted one over each track on the drum). Such a device was already available as a standard peripheral from ICT, but it would have to be modified to have two completely independent sets of read-write heads - one set each for each of the mainframes. The tracks on the drum would be configured as eight sets of in-boxes and out-boxes whereby potentialy eight programs (four in each mainframe) could post transactions to be "picked up" and processed by another program.

A prototype of this "multi-headed" drum was in fact built at the ICT factory in West Gorton and tested using two separate mainframes. The prototype drum actualy sported four complete sets of read/write heads spread at 90° around the periphery, and could thus have supported the interconnection of four independent mainframes.

As it turned out, the limitations encountered by GAK were not related to hardware capacity, and the machine could easily handle whatever was thrown at it using a little over one eight-hour shift per day. The real limitations were encountered in converting literally hundreds of old tabulator-based processes to computer programs. This was exacerbated by two factors:

So the backup plan involving two mainframes interconnected via multi-headed drum never came to fruition - at least not during my remaining time in Holland until early 1969.

- Being a government organization with strict rules and procedures for promotion of civil servants, the programming staff were selected based seniority rather than any aptitude or experience in programming - many of them close to retirement after decades of routine clerical activities.

- A ruling was made by senior management that all program coding should be done in assembler. The justification for this had nothing to do with efficiency or similar reasons, but fear of losing staff if they became experienced in something like Cobol. The idea that Cobol skills could be used by a programmer to write code for a completely different machine (such as IBM) was sufficient to have the case of Cobol Manuals (supplied by ICT) to be quickly locked up and away from prying eyes lest anybody should get any ideas about looking for a job elsewhere.